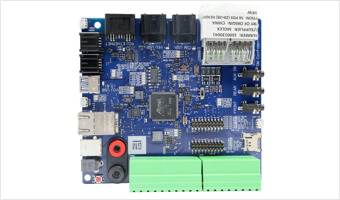

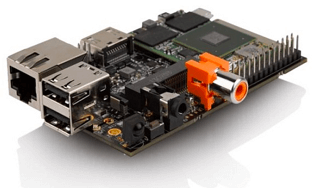

| No. | Item | PCB Assembly Capabilities |

|---|---|---|

| 1 | MOQ | 1 PCS |

| 2 | SMD Standard | IPC-A-610 |

| 3 | Lead Time | 24 hours expedited service; 3-4 days for prototype PCB assembly |

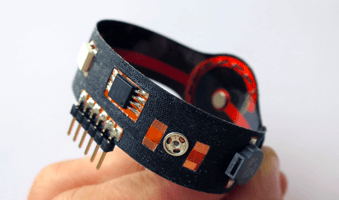

| 4 | Board Size | L50*W50mm ~ L510*W460mm |

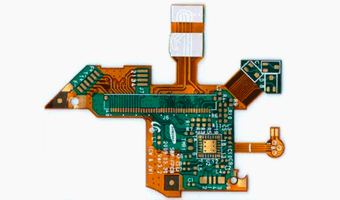

| 5 | Board Type | Rigid PCB, Flexible PCB, Metal Core PCB, Rigid-Flex PCB |

| 6 | Min. Component Package | 01005(0.4*0.2mm) |

| 7 | Max. Component Size | Unlimited |

| 8 | Maximum Component Assembly Accuracy (100FP) | ±0.035mm(±0.025mm) Cpk≥1.0 (3σ) |

| 9 | Surface Finish | lead/lead-free HASL, immersion gold etc. |

| 10 | Assembly Types | Surface mount, Through-hole, Mixed technology (SMT & Thru-hole) |

| 11 | Component Sourcing | Full turnkey (All components sourced by PCBGOGO), Partial turnkey, Kitted/Consigned |

| 12 | Component Types | BGA 0.2mm pitch with X-ray testing, Passive components, Hard metric connectors, Cable & Wire, Bulk |

| 13 | SMT Parts Presentation | Cut tape, Partial reel, Reel, Tube, Tray, Laser-cut stainless steel |

| 14 | Cable Assembly | Custom cables, cable assemblies, wiring looms/harnesses and power leads |

| 15 | Stencils | Stencil with or without frame (offered free by PCBGOGO) |

| 16 | Inspection | Visual inspection; AOI checking; BGA placement – X-RAY checking |

| 17 | Assembly Capability | 3-4 Million Soldering Leads per Day |

| 18 | DIP Component Processing | 100 Thousand Soldering Leads per Day |

|

Note:

Learn more about our PCB Assembly Capabilities on

PC Terminal

|

||

Testing & Inspection Capabilities

We not only assemble PCBs, but also do a thorough testing of the assembled boards. This ensures that the

assembled circuit board is free from any defects. Here are our Testing & Inspection Capabilities:

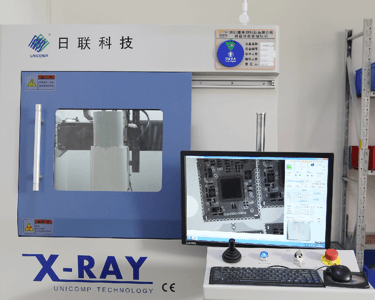

X-ray Testing

This testing is commonly performed on Quad-flat No-lead (QFN) PCBs, and Ball Grid Arrays (BGAs).

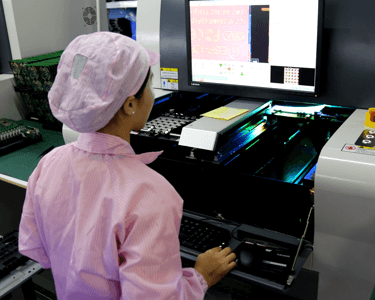

Automated Optical Inspection (AOI)

We perform the automated optical inspection to check whether any components are missing. The solder

paste, polarity, and 0201 components are also checked in this inspection.

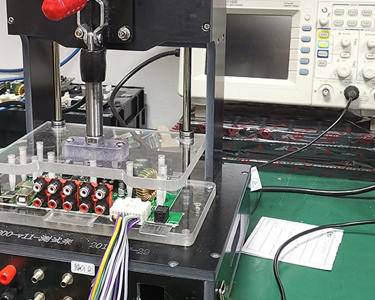

Functional Testing

In this, we check the functionality of the PCB, and ensure whether the performance is according to

the expectations.

Visual Inspection

As the name implies, visual inspection involves a general quality check of the circuit board.

PCB Testing

Inspection

Inspection